Horizontal directional drilling

Directional drilling technology occurred in the US in the 70s and was developed based on the technology of deep drilling.  HDD method undergone rapid development and approved in the field of construction as trenchless technology of laying underground utilities. HDD technology at the LLC "Budyvelnyk-3" is used in cases where traditional methods to perform the work is difficult or impossible. Mostly it is the construction of new underground utilities, and repair work of existing pipelines to increase their diameter and capacity. This work can be done with pipelines made of plastic, metal, cast iron and other materials. Works by HDD method are performed under natural and artificial objects: shipping and mountain rivers, lakes; roads and railways; within dense urban infrastructure; protected areas, parks, public gardens.

HDD method undergone rapid development and approved in the field of construction as trenchless technology of laying underground utilities. HDD technology at the LLC "Budyvelnyk-3" is used in cases where traditional methods to perform the work is difficult or impossible. Mostly it is the construction of new underground utilities, and repair work of existing pipelines to increase their diameter and capacity. This work can be done with pipelines made of plastic, metal, cast iron and other materials. Works by HDD method are performed under natural and artificial objects: shipping and mountain rivers, lakes; roads and railways; within dense urban infrastructure; protected areas, parks, public gardens.

Indisputable advantages of trenchless HDD construction method of underground utilities are:

• preservation of the natural landscape and ecological balance of rivers, lakes, forests, and the existing infrastructure of dense residential development of cities with numerous underground utilities;

• works in soils of any complexity - from water saturated "club mosses" to rocks;

• works in soils of any complexity - from water saturated "club mosses" to rocks;

• high precision - drilling process is constantly monitored and adjusted with the help of special locations;

• high speed construction - no need to stop the movement of road and rail transport and to recover green spaces and urban infrastructure objects;

• reducing construction costs - no need to involve more workforce and earth-moving machinery.

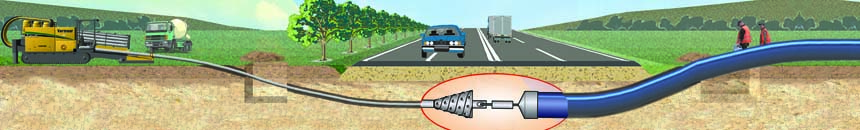

Laying of underground communications by HDD method with using special technics is performed in several stages:

1. PILOT DRILLING. Initially implemented on a given trajectory drilling a pilot hole with a diameter of about 3.9 inches (7.6 - 22.9 cm). Drilling head made of special ultrastrong materials, allows to perfoerm drilling in stony rocks. In addition, radio transmitting probe is placed in the middle of the drilling head, which with location system of high accuracy notify operators about drilling trajectory.

2. EXPANSION. After pilot drilling a hole is extended to the desired diameter in one or more stages. To do this, the appropriate size expander is used. In the formation of the hole its walls are strengthened constantly using special drilling mud - bentonite, which always comes in the formed channel.

3. PIPELINE PULLING. At the final stage one or more pipelines are pulled to an expanded canal of the desired diameter. Light pulling of tubes to the channel is provided by bentonite. It should be noted that the tubes used for the HDD construction can be both polyethylene and steel or cast iron.

© «БУДИВЕЛЬНИК–3» 2005 - 2025